This is because simulation processes generate large volumes of data in different formats and systems, including input and output data, simulation models and results.

Simulation Process

& Data Management

Higher productivity, efficiency and reliability in simulation processes

Today, simulation plays a decisive role in the development of new products. It has become an indispensable tool in numerous industries. By integrating the simulation process into the product development process, you can achieve sustainable benefits and stay one step ahead of the competition. You accelerate development cycles, reduce costs through fewer physical prototypes, save energy and materials, increase product quality through early error detection and optimized performance parameters, reduce risks, promote innovation through low-risk experimentation, and cope with increasing product complexity due to new technologies such as IoT, autonomous systems and artificial intelligence.

End-to-end traceability of data flows

SimData Manager, the leading standard solution for Simulation Process & Data Management (SPDM), is the key to significantly reducing the effort required to manage simulation processes, lowering costs and increasing the quality of results at the same time. SimData Manager provides the basis for automating processes, managing data centrally and ensuring complete traceability.

Design, implementation and evaluation of simulations

The advantage of SimData Manager lies in the combination of several modules that address the different challenges you face every day when managing simulation data and processes. These include

Process automation and repeatability

because simulations often consist of complex, repetitive workflows that are managed manually. This can lead to errors, loss of time and a lack of traceability.

Communication and collaboration

because everyone involved should always be on the same page and use the right data.

Model and variant management

because in practice, various simulations with different parameter and model variants are carried out for optimization purposes.

Quality assurance and compliance

because simulations must be carried out correctly in order to meet the requirements (e.g. legal or internal company specifications).

Consistency and traceability

because development processes must be traceable at all times.

SimData Manager helps to improve the efficiency, accuracy and transparency of simulation processes and enables companies to master the challenges of modern, simulation-based development.

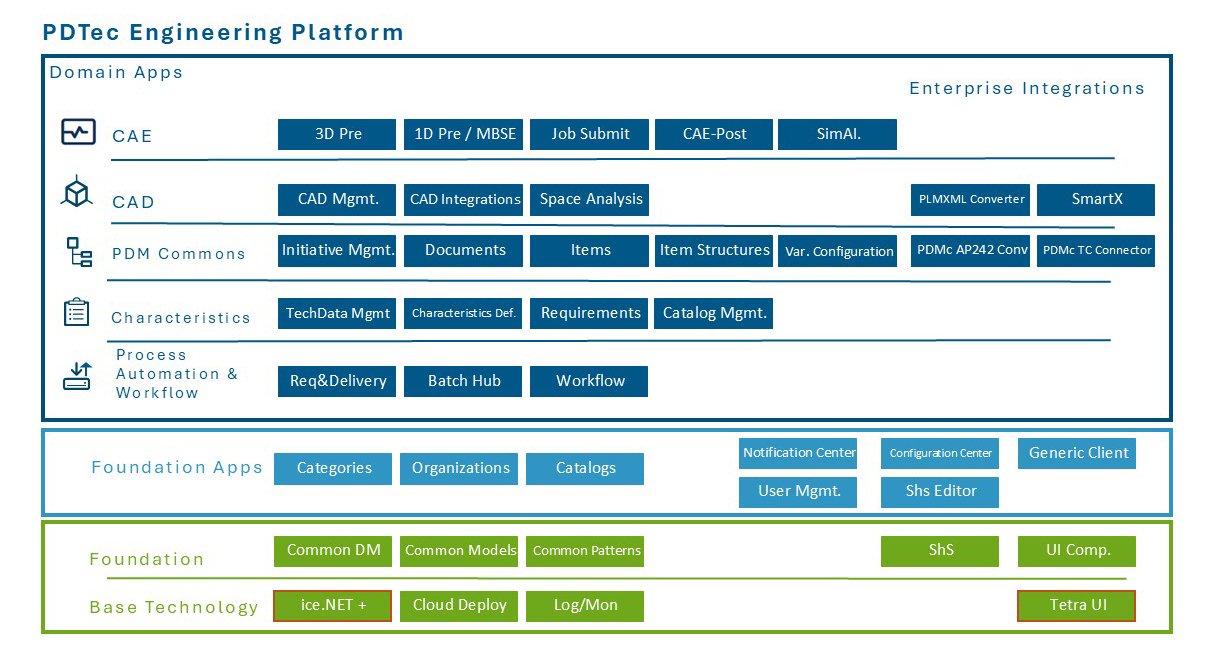

PDTec Engineering Platform

SimData Manager is based on the PDTec Engineering Platform, the leading component architecture that sets new standards in areas such as composability. Designed for modularity, in which the software is divided into individual functional components, SimData Manager meets your future requirements for openness and flexibility. Not only does this make it easier to integrate new functions and technologies, but your SPDM solution can also grow in line with increasing requirements. This gives your software strategy more investment security and future viability!

The advantage of SimData Manager lies in the combination of innovative modules

FAQs

What advantages does the SimData Manager offer for CAE data?

The SimData Manager enables versioned management and traceability of CAE data, from input data to results. This ensures a high level of transparency and control over all CAE processes.

How does the SimData Manager support the efficiency of simulations?

With modules such as “Run Setup” and “Evaluation”, the SimData Manager offers a high level of automation, standardization and intuitive evaluation functions that make the setup and evaluation of simulations efficient.

Why is the SimData Manager future-proof?

The SimData Manager is flexible and expandable through Python and Rest API, supports secure cross-site data exchange and integrates PLM, cloud deployment and SaaS, providing long-term planning security.